Closed-process containment, optimized processes, accelerated speed-to-market —our team is passionate about exceeding clients’ expectations

Route options are valuable when approaching API production, and BIOVECTRA offers robust microbial fermentation and chemical synthesis capabilities. Many of our programs utilize microbial fermentation to complete designated transformation steps, and the product is then seamlessly handed off to our synthetic small molecule team for further processing.

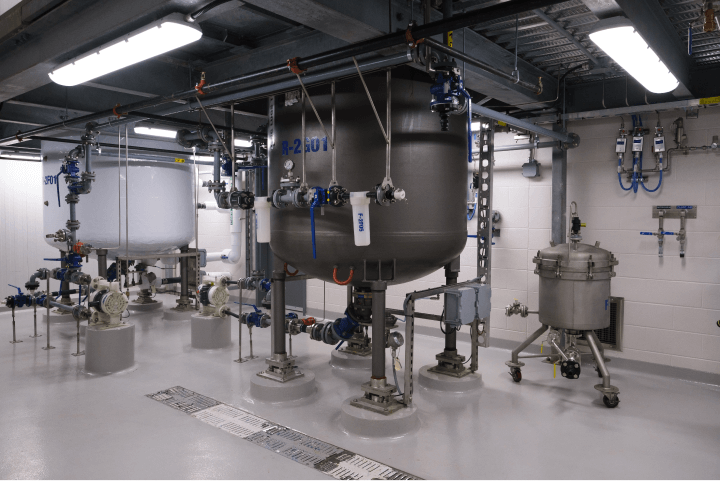

We provide commercial microbial fermentation capabilities, offering full support throughout products’ life cycles. Clients come to us with complex problems that require flexibility and creative solutions. Our experience and dedication give them the confidence that we can execute their programs successfully.